Please Note:

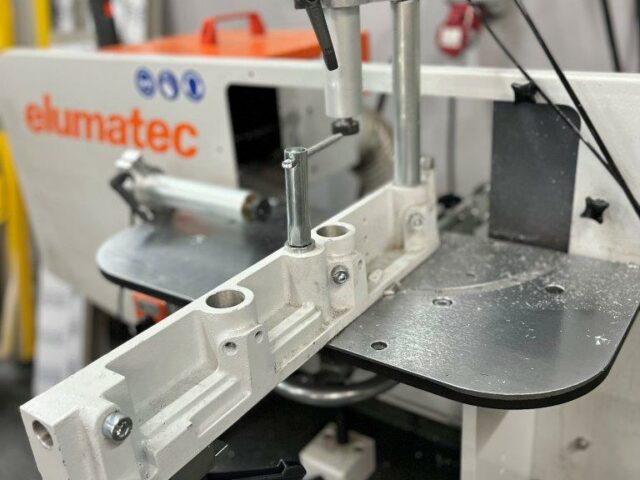

The machinery displayed on this page is not for sale.

We use them to manufacture custom sized aluminium doors and windows.

The double header saw has a high standard of accuracy and boasts of exceptional performance characteristics, including ruggedness and reliability. It is the ideal tool for cutting aluminium in various thicknesses and at different angles.

View moreCopy routing is the quickest and most effective method for making cut-outs of any shape in hollow sections & extrusions. The reliability and versatility has been proven under years of continuous production conditions.

View moreThe crimping machine uses force and pressure for corner crimping of aluminium windows and doors.

View moreHere we store sheets of different types of glass and cut them to a desired size and shape.

View moreThe machine is suitable for grinding straight edges of flat glass of different sizes and thickness. Rough grinding, fine grinding, polishing of flat edge and arris beveling are some of the functions it produces.

View moreDouble glazed windows consist of two layers of glass with an air gap in between them. The two layers are joined with a Dura Platform Spacer System. This creates better insulation and noise reduction. This creates nearly twice the insulation as single glazed units. Once sealed, the unit becomes airtight.

View moreThis part of our workshop is designated for the manufacturing of Casement 30.5 goods

View moreThis part of the workshop is our latest addition to the business. More space and machinery allows for a much better flow in the production process.

View moreWe use this space in our workshop for finished aluminium products. We also store double glazing and toughened glass here.

View more